What Is a CVT Transmission? How It Works, Reliability, and Should You Buy One?

CVT Transmission Guide

This article was written to address the most common questions and misconceptions about CVT (Continuously Variable Transmission) systems using a technical yet easy-to-understand approach. It explains what a CVT is, how it works, why it is sometimes criticized, and which type of drivers it actually makes sense for.

What Is a CVT Transmission?

A CVT is a type of automatic transmission that can change gear ratios seamlessly instead of relying on fixed gears. Unlike traditional manual or automatic transmissions with clearly defined gears such as 1st, 2nd, or 3rd, a CVT theoretically offers an infinite number of ratios. The main goal is to keep the engine operating in its most efficient RPM range at all times.

Mechanical Structure of a CVT

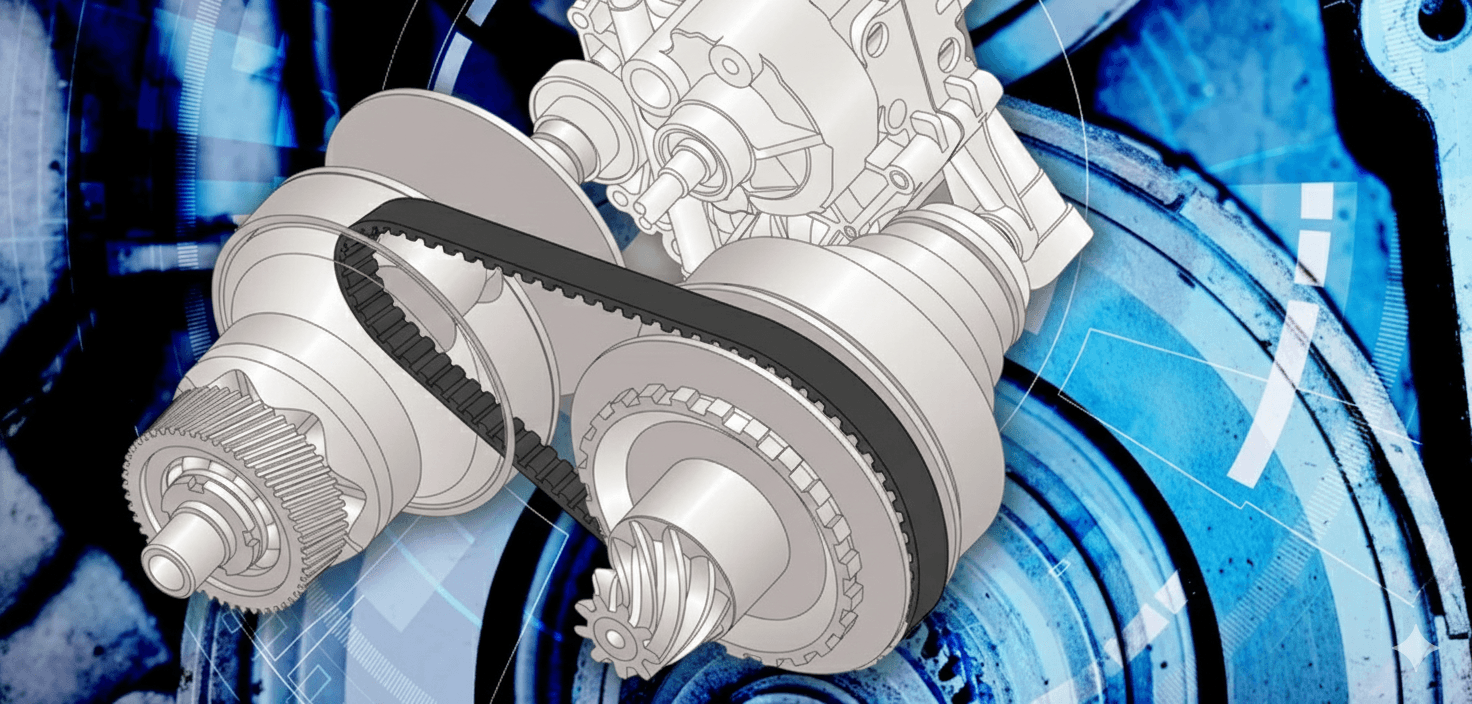

A typical CVT consists of four main components:

- Input pulley (receives power from the engine)

- Output pulley (transfers power to the wheels)

- Steel push belt or chain

- Hydraulic control system and transmission control unit (TCU)

This architecture is the key element that differentiates a CVT from traditional gear-based transmissions.

CVT

How the Belt–Pulley System Works

Each pulley in a CVT is made of two opposing conical surfaces. When these cones move closer together, the belt rides higher, increasing the effective diameter. When they move apart, the belt drops lower, reducing the diameter.

- Small diameter: vehicle launch and acceleration (higher engine RPM)

- Large diameter: steady cruising and lower engine RPM

The critical principle is that as one pulley increases in diameter, the other decreases. This allows the gear ratio to change continuously and smoothly without interruption.

Why CVT Is Considered to Have “Infinite Ratios”

Conventional transmissions have noticeable gaps between gears. In a CVT, ratio changes occur gradually and continuously. As a result:

- There are no shift shocks

- Acceleration feels smooth and uninterrupted

- The engine remains within its optimal efficiency range

This characteristic is both the CVT’s greatest advantage and, for some drivers, its most unfamiliar trait.

“Why Does a CVT Feel Like It’s Revving?” – The Technical Explanation

One of the most common criticisms of CVT transmissions is the way engine RPM behaves during acceleration.

When the accelerator pedal is pressed, the CVT control unit:

- Calculates the most efficient RPM for acceleration

- Holds the engine at that RPM

- Increases vehicle speed by changing the ratio instead of shifting gears

As a result, engine speed does not rise and fall like in a conventional transmission. To drivers accustomed to traditional gear changes, this can feel like the engine is “revving loudly without accelerating,” even though the vehicle is gaining speed normally. This behavior is a natural consequence of CVT design.

Why Do CVTs Have Torque Limits?

In CVT systems, power is transferred through friction between the belt and pulleys rather than through fixed gears. Under excessive torque:

- The belt experiences increased stress

- Hydraulic pressure rises significantly

- Heat buildup increases

For this reason, CVTs are typically paired with low- to mid-torque engines. High-performance engines or those producing sudden torque spikes are generally not well suited to CVT transmissions.

CVT Manufacturers and Brands That Use Them

Most CVT transmissions are not developed directly by vehicle manufacturers. Instead, they are produced by specialized transmission companies and adapted with brand-specific software.

Major CVT manufacturers include:

- Jatco: The world’s largest CVT producer. Widely used by Nissan, Renault, Mitsubishi, Suzuki, Dacia, and Infiniti.

- Aisin: Part of the Toyota Group. Supplies CVTs for Toyota, Lexus, Mazda, and some Subaru models.

- Punch Powertrain: Commonly used in Asian and Chinese markets, including brands like Geely, Chery, and Proton.

- Subaru (Lineartronic): One of the few automakers that develops its own CVT systems, optimized for AWD compatibility.

- Honda: Uses largely in-house CVT designs, often praised for delivering a more natural driving feel.

When evaluating a CVT-equipped vehicle, the question should not only be “Does it have a CVT?” but also “Which CVT is it?”

Other Types of CVT Systems (Brief Overview)

While belt-and-pulley CVTs are the most common, other variations exist:

- Torque-converter-assisted CVTs

- e-CVT systems used in hybrid and electric vehicles

- Planetary-gear-based hybrid CVT designs

Each uses a different operating principle and deserves separate, detailed discussion.

Common Myths About CVT Durability

“CVTs fail easily.”

Incorrect. CVTs fail quickly when poorly maintained or misused. With proper care, they can be durable.

“All CVTs are the same.”

Incorrect. Manufacturer design, software calibration, and usage patterns dramatically affect reliability.

“The belt always snaps.”

Rare. Belt failure usually results from incorrect fluid, low pressure, or prolonged abuse.

Common CVT-Related Issues

Most CVT problems develop gradually rather than suddenly. Common symptoms include:

- Shuddering during launch or low-speed driving

- RPM fluctuation during acceleration

- Delayed throttle response

- Performance loss when overheated

- Warning lights or limp mode activation

These issues are often linked to degraded CVT fluid, insufficient hydraulic pressure, or pulley wear. Early diagnosis can prevent major failures.

Driving Habits That Shorten CVT Lifespan

- Aggressive throttle input with a cold transmission

- Frequent hard acceleration and kickdown usage

- Holding the vehicle in Drive on steep inclines for long periods

- Shifting between Reverse and Drive before coming to a complete stop

- Neglecting CVT fluid changes or using incorrect fluid

CVTs are designed for smooth and progressive driving. Aggressive habits significantly reduce longevity.

What to Check Before Buying a CVT Vehicle

When purchasing a CVT-equipped car, it’s important to look beyond the “automatic transmission” label.

Key points to consider:

- Identify the CVT manufacturer (Jatco, Aisin, Punch, etc.)

- Confirm engine torque compatibility with the CVT design

- Review service records for CVT fluid replacement

- Test drive the vehicle both cold and fully warmed up

- Check for shuddering, RPM fluctuation, or delayed response

- Avoid CVT if high-performance driving is a priority

The most common mistake is evaluating a CVT with the same expectations as a conventional automatic transmission.

Best Practices for CVT Longevity

CVT lifespan depends heavily on driving habits. Small changes can produce major mechanical benefits.

Recommended practices:

- Drive gently during the first few minutes after cold start (CVT fluid is less effective when cold)

- Avoid frequent wide-open throttle inputs (reduces belt and pulley stress)

- Use Neutral during long uphill stops (relieves pulley load and hydraulic pressure)

- Never shift between Drive and Reverse while the vehicle is moving

- Replace CVT fluid at appropriate intervals (fluid controls lubrication, pressure, and friction)

CVTs perform best under smooth and balanced driving conditions.

Is a CVT Transmission Worth Buying? (Short Answer)

Yes—for the right driver. CVT transmissions are well suited for urban driving, smooth acceleration, and comfort-focused users. They are not ideal for aggressive driving, heavy towing, or high-performance demands. With proper use and maintenance, modern CVTs offer a reliable and refined automatic transmission option.

Who Should Choose a CVT?

Suitable for:

- City-focused drivers

- Those prioritizing comfort and smoothness

- Calm and progressive driving styles

- Stop-and-go traffic conditions

Not ideal for:

- Sport-oriented drivers

- Frequent hard acceleration users

- Heavy-load or performance-focused applications

CVT Maintenance and Longevity Facts

Some manufacturers label CVT fluid as “lifetime,” but real-world experience suggests otherwise.

- CVT fluid replacement is typically recommended every 60,000–80,000 km based on manufacturer service documents and transmission supplier bulletins

- Severe city use may require shorter intervals

- Incorrect fluid is one of the leading causes of CVT failure

With proper maintenance and driving habits, CVTs can exceed 200,000 km without major issues.

Mechanics’ Perspective on CVT Transmissions

Negative opinions about CVTs often stem from early-generation designs and lack of familiarity. CVTs require specialized knowledge and should be serviced by technicians experienced with this transmission type.

Frequently Asked Questions

Do CVTs cause problems on long highway trips?

No. Highway driving is generally less stressful for CVTs than stop-and-go city traffic.

Do CVTs roll back on hills?

Not when functioning properly. Rollback may indicate fluid or pressure issues.

Can CVTs be repaired?

Yes, but repairs should be performed by CVT-specialized workshops.

Do CVTs improve fuel efficiency?

Generally yes, especially in city driving, due to optimal engine RPM control.

Source and Technical Reference Note

The technical information in this guide is based on service manuals published by CVT manufacturers (such as Jatco and Aisin), official maintenance documentation from vehicle manufacturers, and long-term field experience from CVT-specialized repair centers. Maintenance intervals reflect real-world operating conditions rather than marketing claims.

Final Thoughts

A CVT transmission is not a flawed system. Misuse, incorrect expectations, and poor maintenance are what create problems. For the right driver and usage profile, a CVT is one of the smoothest and most comfortable automatic transmission options available today.

CVT transmissions are not bad—they are simply misunderstood and often used incorrectly.